The most versatile counterweight guide in the industry

- EXCEPTIONAL APPLICATION RANGE

- MINIMIZED NOISE AND VIBRATION

- OPTIMIZED RIDE QUALITY AND FLOAT

- DURABLE, ENGINEERED DESIGN

- QUICKER AND EASIER INSTALLATION

Product Description

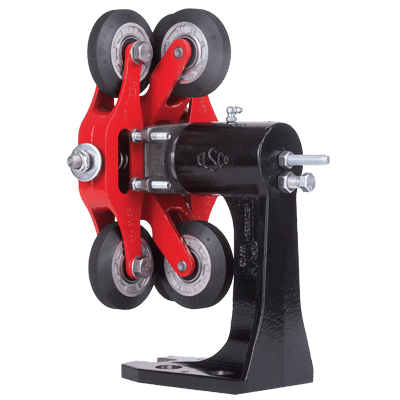

Patented design features on the Model C roller guide ensure counterweights in high speed applications run just as quietly in the hoistway as the car. Slim design allows for use on a wide range of elevator applications and rail sizes, and it can even be used as a car guide where a smaller roller is required for clearance.

Designed for elevator counterweights up to 1,200 fpm or 10,000 lbs capacity in mid- to high-rise buildings, the Model C is a high-speed 6-wheel paired-roller guide with spring suspension, an adjustable stop on the face arm and six premium 3-1/4″ diameter neoprene roller wheels. Find the full range of applications and rail compatibility here

Engineered and tested to meet ASME A17.1/CSA B44 and EN81 standards. ELSCO’s Model C roller guide is constructed from precision machined, ductile iron castings and is assembled using quality parts to ensure your elevator ride will GO UNNOTICED.

-

Neoprene Rubber Roller Wheels

- Precision manufactured using ELSCO’s proprietary neoprene rubber tread compound

- 65A durometer tread dampens vibration and reduces noise even in high-speed applications

- Precisely ground tread profile provides a balanced and concentric roller

- High-memory tread characteristics prevent flat spotting

-

Precision Ball Bearings

- Industrial grade, high quality ball bearings will last for millions of cycles

- Dual bearing construction provides the roller extra stability, ensuring a true ride, free of noise and vibration

-

Tandem-Roller Arms

- 6-wheels give added stability that can easily handle higher speeds and capacities

- 6-wheel design steps over misaligned rail joints minimizing counterweight or in-car vibration at high speeds

-

Fully Adjustable Stabilizing Springs

- Independently adjust the pre-load force of the rollers on the rail to minimize bumps and vibration and ensure proper dampening

- Allow for maximum adjustability to optimize reduction in peak-to-peak lateral forces which improves ride quality

-

Adjustable Stop

- On the face arm allows control of the overall float of the counterweight between the rails in a post-to-post direction

- Allows for precise final adjustments to deal with troublesome hoistway issues

-

Robust Casting and Design Features

- Machined grease groove around the hub ensures improved distribution of grease to reduce friction

- Precisely machined castings ensure the final assembly is of the highest quality

-

Innovative Design Features

- Patented adjustment features are designed for quick and simple installation, reducing installation costs

- Hub adjustment and adjustable stop assemblies are pre-installed at the factory

- Face roller wheel rail pressure is easily adjusted to recommended pressure by turning the hub adjustment screw