The next level in ride quality

- ULTIMATE RIDE QUALITY

- MINIMIZED NOISE AND VIBRATION

- TAKE CONTROL OF FLOAT

- DURABLE, ENGINEERED DESIGN

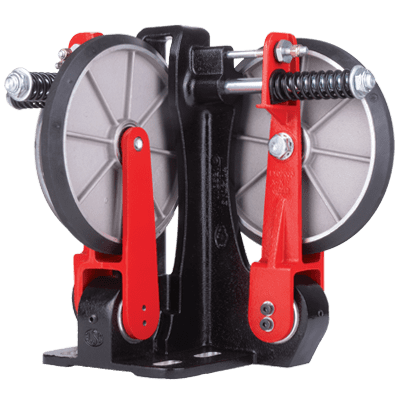

Product Description

The Express-3 provides first-class ride quality in very high-speed applications where it’s needed most. Patented vibration-suppressing pivot bushings and 10” (254 mm) neoprene roller wheels isolate the elevator cabin from unsettling noise and vibration.

Designed for elevator cars up to 2,000 fpm (10 m/s) or 5,000 lbs (2,300 kg) capacity in high-rise buildings, the Express-3 is a high-speed three-wheel roller guide with spring suspension, adjustable stops in all directions, and three premium 10” (254 mm)diameter neoprene roller wheels. Find the full range of applications and rail compatibility here

Engineered and tested to meet ASME A17.1/CSA B44 and EN81 standards, ELSCO’s Express-3 roller guide is constructed from precision machined aluminum and ductile iron castings and is assembled using quality parts to ensure your elevator ride will GO UNNOTICED.

-

Ten-Inch Roller Wheels

- Extra large diameter rollers reduce wheel RPMs at high speeds resulting in a smoother, quieter ride

- Help deal with hoistway imperfections that can be especially troublesome in high-rise buildings

-

Patented Elastomeric Pivot Bushings

- Provide additional suppression of vibrations, more prevalent in higher speed applications, resulting in improved passenger comfort and tenant satisfaction

-

Neoprene Rubber Roller Wheels

- Precision manufactured using ELSCO’s proprietary neoprene rubber tread compound

- 65A durometer tread dampens vibration and reduces noise

- Precisely ground tread profile provides a balanced and concentric roller

- High-memory tread characteristics prevent flat spotting

- Excellent resistance to oils, chemicals and UV for extended life

-

Precision Ball Bearings

- Industrial grade, high quality ball bearings will last for millions of cycles

- Dual bearing construction provides the roller extra stability, ensuring a true ride, free of noise and vibration

- Precision bearing press process during assembly at ELSCO ensures perfect fit, alignment and quality

-

Fully Adjustable Stabilizing Springs

- Independently adjust the pre-load force of the rollers on the rail to minimize bumps and vibration and ensure proper dampening

- Allow for maximum adjustability to optimize reduction in peak-to-peak lateral forces which improves ride quality

-

Adjustable Stops

- Allow independent control of the overall float of the elevator car between the rails in post-to-post and front-to-back directions

- Allow for precise final adjustments to deal with troublesome hoistway issues that adversely affect ride quality

-

Robust Components

- Precisely machined castings ensure the final assembly is of the highest quality

- Tested to meet applicable codes and standards ensuring the guides provide a lifetime of reliable performance