Whether you’re installing new guides or making a service call, we’re always here to help with tips, answers, and expert advice about how to achieve the best performance.

Share the short check list below with your team, to help them save time on-site, avoid common frustrations and improve elevator ride quality.

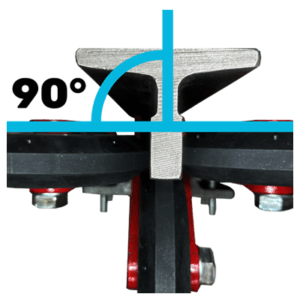

1. Roller guide and rail alignment

- Roller guide must be aligned perpendicular to guide rail

- Adjust roller guide until the alignment is correct

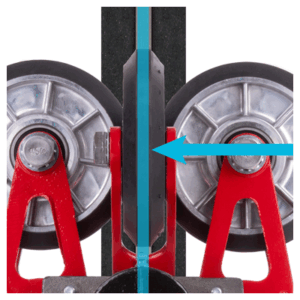

2. Roller Wheel Positioning

2. Roller Wheel Positioning

- Face roller wheel should be centered on face of guide rail

- Adjust roller guide left or right to center face roller wheel

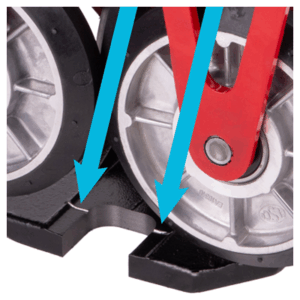

3. Bracket-to-face of guide rail distance

3. Bracket-to-face of guide rail distance

- Install with correct distance from face of guide rail to front of bracket

- Align scribe line on front of bracket with face of guide rail

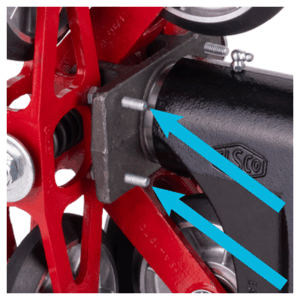

4. Roller Wheel Preload (25 – 50 lbf)

4. Roller Wheel Preload (25 – 50 lbf)

- Preload should be between 25 – 50 lbf on side and face roller wheels

- It should be possible to skid roller wheels on the guide rail with moderate effort

Side Roller Wheel Preload

- Adjust preload force on guide rail using the side arm adjustment nut

Face Roller Wheel Preload

- Adjust preload force on guide rail using the hub adjustment screw

- Turn side arm adjustment nut or hub adjustment screw clockwise to increase the force and counterclockwise to reduce it, until the correct force is achieved

5. Side Arm Roller Wheel Tracking

5. Side Arm Roller Wheel Tracking

- Side arm tracking screws are preset at the factory. DO NOT adjust unless required

- Top & bottom roller wheels must be aligned parallel to face of guide rail

- Adjust side arm tracking screws until top and bottom roller wheel spacing from the guide rail edge is equal

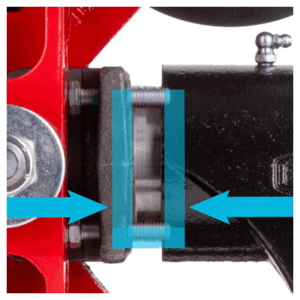

6. Bracket & Hub Gap

6. Bracket & Hub Gap

- Gap between bracket and hub should be 3/8″

- Use scribe line on hub barrel to verify correct spacing

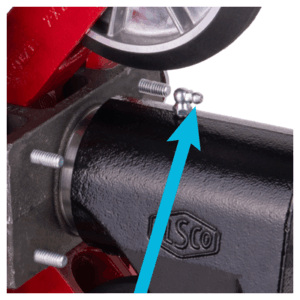

7. Lubrication

7. Lubrication

- Inside of bracket & outside of hub barrel must be greased

- Use grease fitting—apply general purpose grease until it appears between hub & bracket

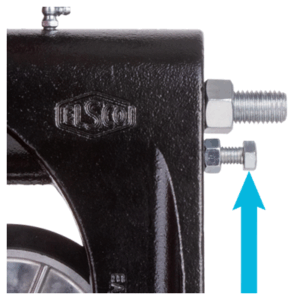

8. Elevator Float

8. Elevator Float

- Float is preset at the factory. DO NOT change adjustable stop screw setting unless float needs adjusted

- Turn adjustable stop screw clockwise to decrease float and counterclockwise to increase float

If you still have questions about installing ELSCO roller guides, don’t hesitate to call ELSCO Customer Service at 410.363.9020, or e-mail us at info@elscoguides.com. We are always available to help troubleshoot technical issues.