Modernizing or installing elevators in active seismic zones?

If your application is in a seismic zone 2 or higher, you may be required to comply with ASME 17.1 section 8.4’s seismic requirements.

ELSCO’s seismic retainer plates and seismic Flex-Mount™ Adjustable Adapter Plates will ensure that the installed roller guides will comply with these code requirements.

Both are engineered and tested to meet ASME A17.1-2013, CSA B44/19, and EN 81-77 requirements for seismic risk in zones 2 or higher.

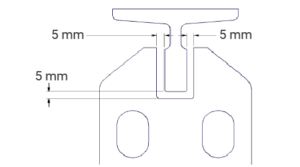

They offer an off-the-shelf solution that addresses both the calculated seismic rail force requirements and the updated retention requirements outlined in subsection 8.4.5, which specifies the maximum clearance between each running face of the rail and the plate, and the required depth of engagement with the rail.

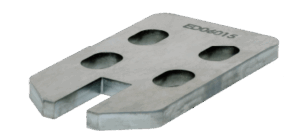

Seismic Retainer Plates

Available for all ELSCO rollers guides and slide guides, rail sizes range from 8# to 30# for elevator cars and range from 5.75# to 18# for counterweights.

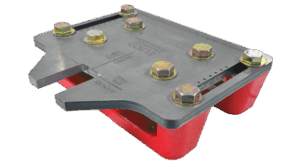

Bolt Pattern Mismatch?

Seismic Flex-Mount™ Adjustable Adapter Plates are also available to make it quicker, easier, and cheaper to install roller guides in seismic zones when the existing bolt pattern and mounting bolt pattern do not line up.**

The maximum capacity for using seismic Flex-Mount™ is 5,000 lbs for cars and counterweights. Seismic Flex-Mount™ are available for Express-3, Model A, Model B and Slide Guides on 15#, 18#, 22# & 30# rails, and for Model C, Model D and counterweight Slide Guides on 8#, 15# and 18# rails.

**Only roller guides with the same bolt pattern as ELSCO’s can mount to ELSCO seismic Flex-Mount™ adjustable adapter plates.